Case History

PRINCIPI DI PORCIA FARM

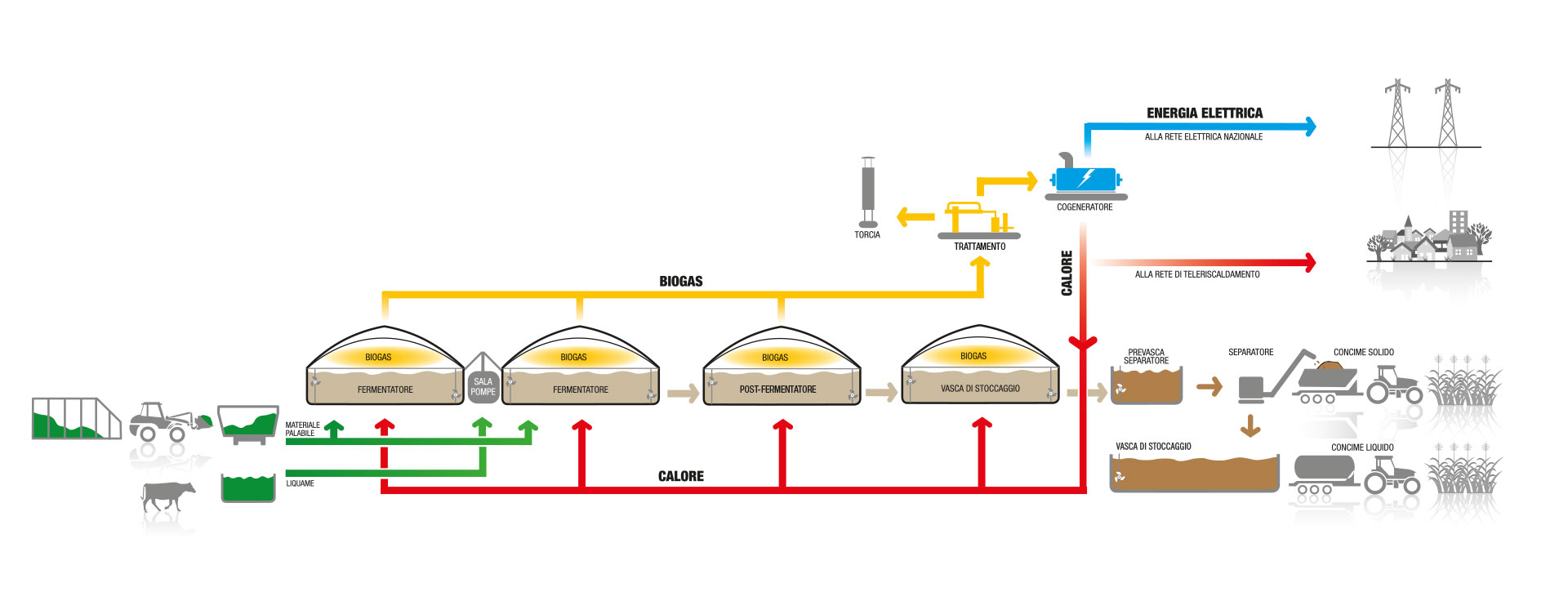

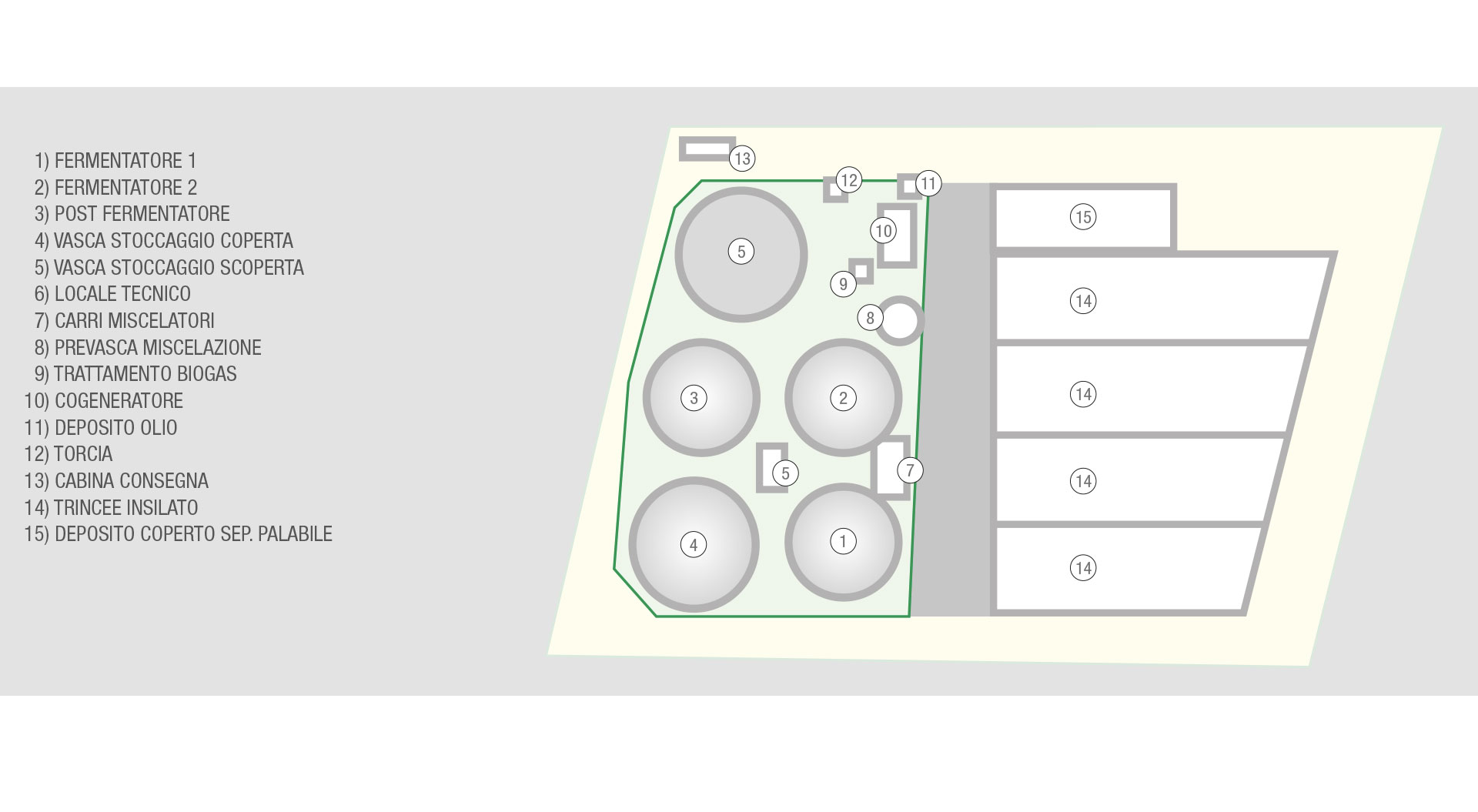

IES Biogas has realized in Azzano Decimo (PN) an innovative and efficient biogas plant made in Italy, perfectly integrated in the production cycle of the company. Realised by IES Biogas, it is able to feed into the national grid up to 999 kW per hour and meet the needs of 3000 families: without waste, without odours, in favour of the environment and the community. The project has effectively completed the self-sufficiency cycle of the farm and winery: everything the plant rejects after treatment, including grape processing waste, is transformed into biogas and energy or returns to the fields as fertiliser. Part of the heat from cogeneration, channelled through a pipeline water system, heats the soil and produces asparagus sold as first fruits. In this way the cycle is perpetuated over time, with a high level of efficiency.

TECHNICAL DATA SHEET // 999 kWe

INSTALLED ELECTRIC POWER 999 kW

| INSTALLED ELECTRIC POWER 999 kW | 999 kW | ||

|---|---|---|---|

| DOUBLE-STAGE MESOPHILIC PROCESS | |||

| Fermenters | n.2 | Ø 25m | h=6m |

| Post-fermenter | n.1 | Ø 25m | h=6m |

| Covered storage tank | n.1 | Ø 28m | h=6m |

| Open storage tank | n.1 | Ø 28m | h=6m |

| Biomass feeder | n.2 | mixed-wagons | 40mc |

| DAILY FEEDING PLAN | |||

|---|---|---|---|

| Bovine sewage | 5 ton | ||

| Cattle manure | 5 ton | ||

| Corn silage | 40 ton | ||

| Triticale silage | 10 ton | ||

| ENERGY EFFICIENCY | |||

|---|---|---|---|

| Annual electricity production | 8.400.000 kWh | ||

| Annual production of biogas | 4.200.000 mc | ||

| Methane concentration (CH4) in biogas | 52-54 % | ||

| COGENERATION GROUP | |||

|---|---|---|---|

| Manufacturer | AB Energy | ||

| Model | Ecomax 10 Bio | ||

| ENGINE | |||

|---|---|---|---|

| Manufacturer | Jenbacher | ||

| Model | J 320 GS-C25 | ||

Biogas is one of the most widely used alternative sources of renewable energy production.

Biogas is the product of microbial degradation of organic substances in the absence of oxygen, a process commonly called anaerobic digestion. It is a mixture of gases, mainly composed of methane (CH4) and carbon dioxide (CO2).

Slurry from the barn, together with corn and triticale silage, is daily put into the two mainly digesters. Here they remain for about 100 days and then pass into the covered storage tank. The process is therefore of “double-stage” type and takes place at a temperature of 38-42 degrees (mesophilia). The “double-stage” technology allows a safe and elastic fermentation process but, above all, guarantees adequate retention times.

The covering of the storage ensures a complete degradation and therefore an efficient exploitation of the biomass used. Moreover, it also allows a greater reserve of biogas and a better desulphurisation (removal of H2S). Desulphurisation is biological, by injection of very small amounts of oxygen. The internal structure and a desulphurisation network offer an excellent surface for the colonisation of the desulphuriser bacteria. The biogas produced is conveyed to the cogenerator, which produces electricity and thermal energy.

The electricity is transferred to the public grid, the heat is reused partly for the fermentation process, partly for the district heating of barns and offices. At the end of the fermentation process the digestate is obtained: a liquid material, completely odourless, with very high agronomic value, with improved characteristics compared to the raw material.

The digestate undergoes a process of solid/liquid separation: the solid that has the consistency, appearance and smell of a “soil-humus”, is distributed in the fields with a manure spreader or sold to specific users such as flower-gardeners.

TO THE BENEFIT OF WATER, AIR AND SOIL QUALITY.